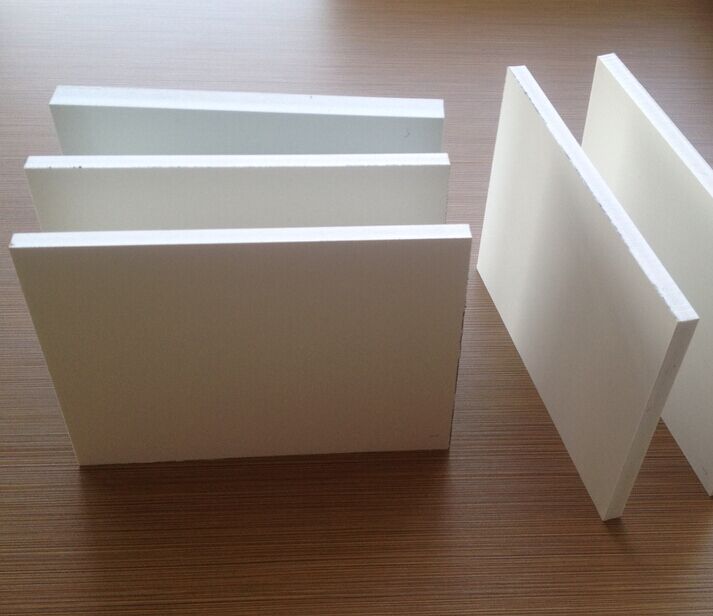

PVC Foam Board density 0.55

1. Light weight

2. Smooth surface and easy printing

3. Good plasticity, excellent in thermoforming

4. High impact

5. Anti chemical corrosion, Non toxic

6. Good heat preservation

7. Good sound insulation and shock absorption

8. Unfading and anti aging

Product Details

The PVC foam board is good substitution of wood. There is white color, black color and many other colorful sheet. The raw material is PVC which with not only features of woodplast, but also light weight and can be printed, Drilling and engraved easily.

Standard size 1220x2440 1560x3050 2050x3050

Thickness 1mm - 25mm

Density 0.33g/cm³ - 0.9g/cm³

Features:

1. Light weight

2. Smooth surface and easy printing

3. Good plasticity, excellent in thermoforming

4. High impact

5. Anti chemical corrosion, Non toxic

6. Good heat preservation

7. Good sound insulation and shock absorption

8. Unfading and anti aging

Applications:

1. Advertising: printing,engraving,cutting,sawing signs, display, exhibition boards .

2. Industrial use: wall claddings, control cabinets and panels, structures for corrosive environments

3.furniture use: kitchen cabinet,models, partitions, upholstery

PVC Foam Board Data Sheet

Testing item | Unit | Testing result |

Tensile strength | MPa | 10-20 |

Bending strength | MPa | 12-20 |

SHORE intensity | D | ≥55 |

Charpy impact strength | KJ/m2 | ≥12 |

Elongation at break | % | ≥10 |

Dimensional shrinkage under heat | % | ±2.0 |

Vicat softening temperature | oc | ≥70 |

Flexural strength | MPa | ≥20 |

Flexural modulus | MPa | 800-900 |

Impact strength | KJ/m3 | 8-15 |

Screw holding capability | N | ≥700 |

Water absorption | % | ≥1.0 |

Fire rating | B1 with self-extinguishing less than 5 seconds | |

Surface density | g/m3 | 0.5-0.7 |

Coefficient of heat conductivity | W/(m.K) | 0.054 |

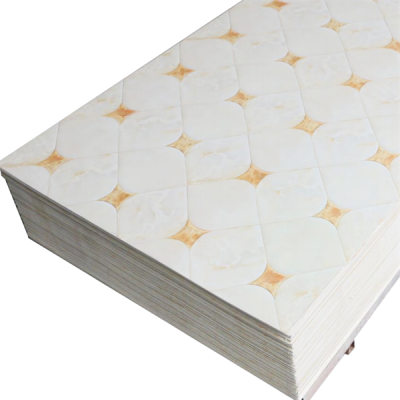

Packing

Send your message to us

Related Products

Related News

What is clear acrylic sheet?

2023-06-13

1.2mm Acrylic Mirror

2023-02-03

Super Clear Acrylic Sheet

2023-02-03

Submitted successfully

We will contact you as soon as possible

Close